|

University of Southampton Institute of Transducer Technology |

Thick-film Magnetostrictive Materials |

This project involves the development of a thick film material with magnetostrictive properties. Magnetostriction is defined as the dimensional change of a magnetic material caused by a change in its magnetic state and the reverse effect by which an applied stress causes a change in the materialís magnetic state. All magnetic materials exhibit varying degrees of magnetostriction, however only some materials exhibit sufficient magnetostriction for practical use. Early magnetostrictive devices were used Nickel as the magnetostrictive material and this principle found use in sonar applications.

In the early 1960ís the magnetostrictive properties of terbium and dysprosium were identified but, due to the low Curie temperatures of the two elements, they were not suitable for use at room temperature. To attempt to produce a material that would exhibit large magnetostriction at room temperature terbium and dysprosium were alloyed with transition metals, in 1971 this led to giant magnetostriction at room temperature of the alloys TbFe2 and DyFe2. Terfenol-D, which has the composition Tb0.3Dy0.7Fe2, provides a magnetostriction of over 1000 * 10-6. This material, in powdered form, is used as the active material in the thick film under development.

It is intended to utilise the thick film as an actuator in MEMs devices as an alternative to using thin film deposition to provide a magnetostrictive layer or the use of piezoelectric thick films which require high electric fields for operation. This project involves the development of a thick film material with magnetostrictive properties. Magnetostriction is defined as the dimensional change of a magnetic material caused by a change in its magnetic state and the reverse effect by which an applied stress causes a change in the materialís magnetic state. All magnetic materials exhibit varying degrees of magnetostriction, however only some materials exhibit sufficient magnetostriction for practical use. Early magnetostrictive devices were used Nickel as the magnetostrictive material and this principle found use in sonar applications.

In the early 1960ís the magnetostrictive properties of terbium and dysprosium were identified but, due to the low Curie temperatures of the two elements, they were not suitable for use at room temperature. To attempt to produce a material that would exhibit large magnetostriction at room temperature terbium and dysprosium were alloyed with transition metals, in 1971 this led to giant magnetostriction at room temperature of the alloys TbFe2 and DyFe2. Terfenol-D, which has the composition Tb0.3Dy0.7Fe2, provides a magnetostriction of over 1000 * 10-6. This material, in powdered form, is used as the active material in the thick film under development.

It is intended to utilise the thick film as an actuator in MEMs devices as an alternative to using thin film deposition to provide a magnetostrictive layer or the use of piezoelectric thick films which require high electric fields for operation.

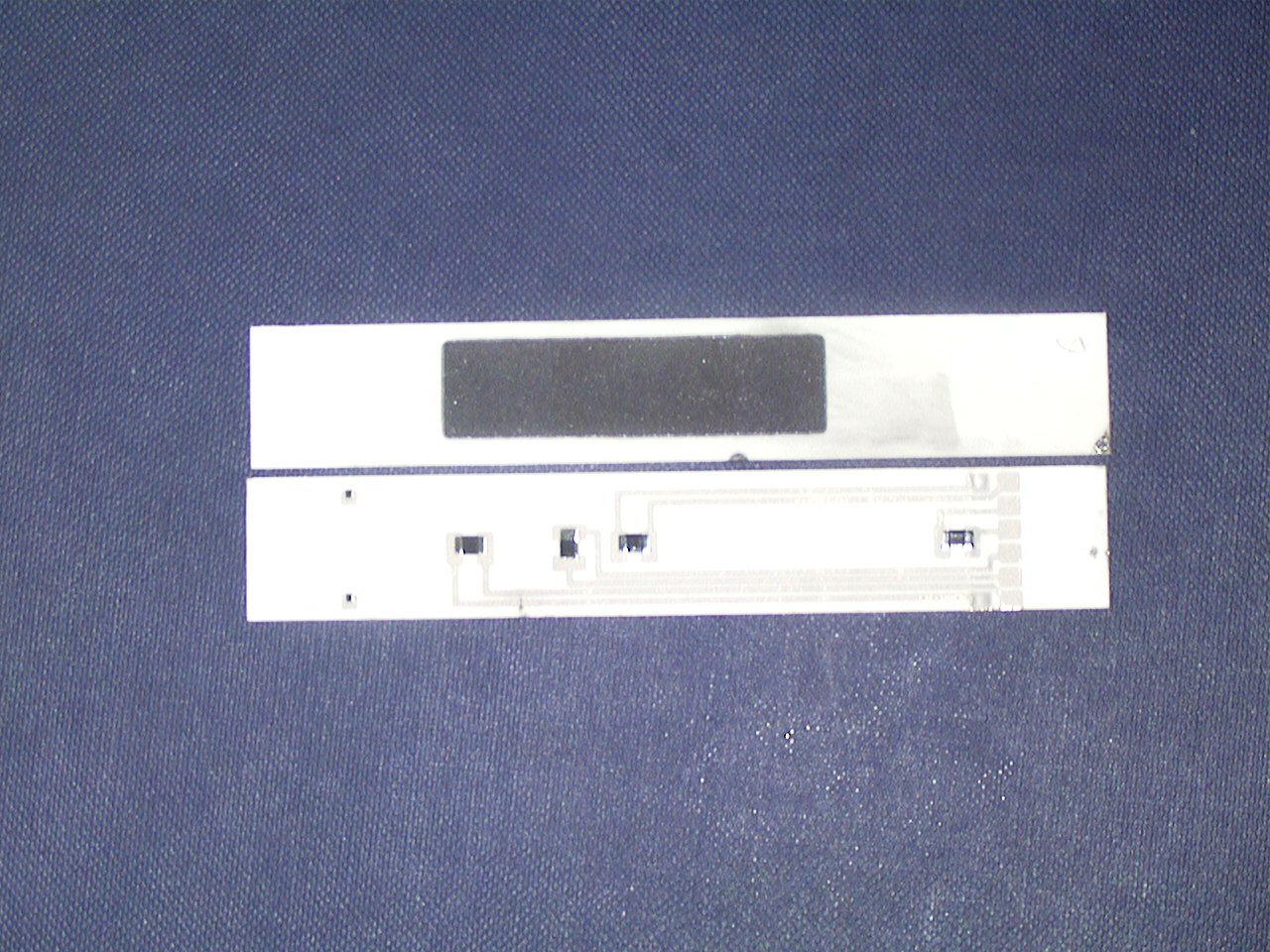

Figure 1 - Thick-film magnetostrictive sample

In the picture the upper sample shows the printed thick film terfenol layer on one side of the alumina substrate and the lower sample shows the thick film strain gauges used to measure the strain which is printed onto the other side on the substrate.