Commercialisation of crystal laser technologies

Researchers at the University of Southampton (UoS) have developed and patented the engineering of nonlinear optical materials for highly efficient wavelength conversion with lasers. This has underpinned the original creation and ongoing development of spinout company Covesion Ltd. Over the impact period, Covesion has become a leader in the supply of crystals and packaged products for use in laser, anti-missile, imaging and quantum technology systems across the defence, communications, laser manufacturing and medical sectors.

Research challenge and context

Engineered nonlinear optical materials are used to change the wavelength of laser light for numerous applications. ‘Quasi-phase-matching’ is a key technique for achieving efficient wavelength conversion. It involves compensating the relative phase between two or more frequencies of light as they propagate through a crystal. It is necessary for the phase relation between the input and generated photons to be maintained throughout the crystal so that the number of generated photons exiting the crystal is maximised. PPLN – periodically poled lithium niobate – is an engineered, quasi-phase-matched material; the orientation of the lithium niobate crystal is periodically inverted to avoid the photons slipping out of phase with each other. This means the number of generated photons will grow as the light propagates through the PPLN crystal, yielding a high conversion efficiency.

Our solution

Since Covesion’s formation, UoS researchers have pioneered a new approach to making optical waveguide devices in PPLN, utilising a combination of zinc diffusion and physical machining. The waveguide format in PPLN provides the capability of tightly focusing a laser beam, significantly boosting the efficiency of the wavelength conversion while maintaining a very high level of power handling. Research under the UK National Quantum Technologies Programme investigated the optimum dicing processes (a form of mechanical sawing used in photonics) required to achieve ultra-smooth surfaces for the zinc-diffused waveguide structures in order to optimise frequency conversion and eliminate the need for time consuming and costly lapping and polishing.

What was the impact?

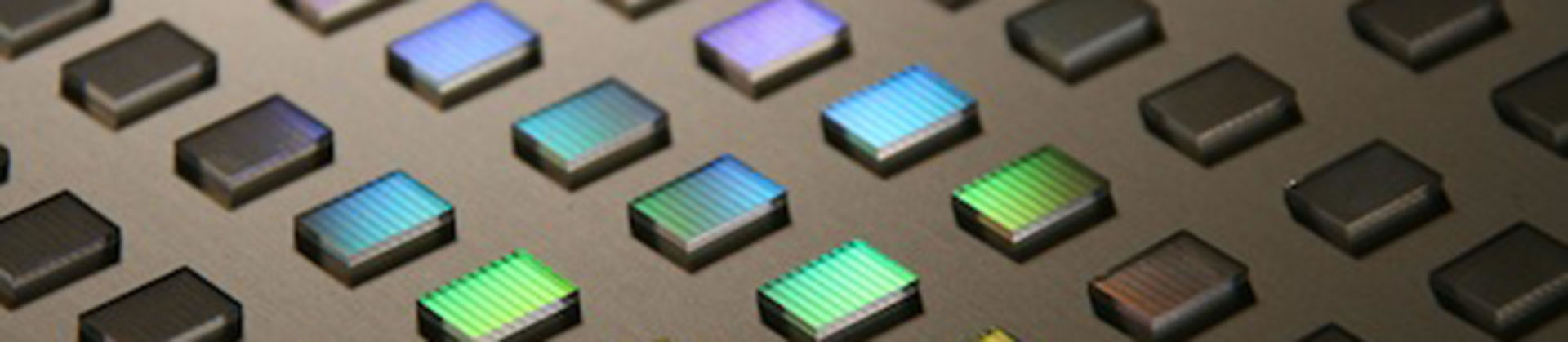

University of Southampton research underpinned the formation of spin out company Covesion and, over the REF 2021 impact period, has been integral to both the optimisation of the company’s MgO PPLN crystals and the creation of new PPLN products. Covesion offers volume manufacture of bespoke crystals for Original Equipment Manufacturer systems; its PPLN devices allow customers to reach wavelengths that cannot be achieved with conventional solid state or diode lasers. The company’s customers include world-leading companies and prestigious research institutes spanning the areas of defence, communications, laser manufacturing and medicine.

Related pages

Visit spinout company Covesion Ltd website